|

1.Using special tool

Flywheel stopper (MD998781), hold the drive plate.

|

|

2.Remove the crankshaft

pulley centre bolt.

| caution |

provide one punch mark on the

head of the crankshaft pulley

centre bolt each time the bolt is removed.

Replace the bolt that already has three punch

marks.

(the evidence of having been tightened three

times)

|

|

|

|

1.Temporarily tighten the

alternator to the alternator bracket.

|

|

2.In accordance with the

tightening order shown in the illustration, tighten the

installation

bolts for the alternator to the specified

torque.

Tightening torque: 47 ± 11

N·m

|

|

1.

| caution |

before installing the

crankshaft pulley centre bolt,

check the number of punch marks on its head.

(the bolt is reusable if it is two or less.) If

the bolt has three punch marks, replace

it.

|

Using special tool Flywheel stopper (MD998781), hold

the drive plate.

|

|

2.Wipe the dirt on the

crankshaft pulley washer using a rag.

3.Using a

rag, wipe the dirt on the crankshaft pulley, the front

flange, the crankshaft

sprocket, the thread hole of the crankshaft and then remove

the grease.

4.Install the front flange and

crankshaft pulley.

5.Apply an appropriate and

minimum amount of engine oil to the threads of crankshaft

pulley centre bolt and lower part of the

flange.

6.Install the crankshaft pulley washer to

the crankshaft pulley centre bolt.

7.Tighten the

crankshaft pulley centre bolt to 110 N·m.

|

|

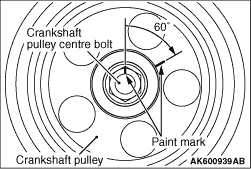

8.Make a paint mark on the

crankshaft pulley centre bolt.

9.Make a paint mark

on the bolt end at a position 60° from the paint mark

made

on the crankshaft pulley in the direction of tightening the

crankshaft pulley centre bolt.

| caution |

- When the tightening angle

is smaller than the specified tightening

angle, the appropriate tightening

capacity cannot be

secured.

- When the tightening angle is larger than

the specified tightening angle, remove

the bolt to start from the beginning

again according to the

procedure.

|

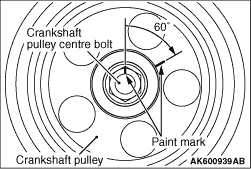

10.Turn the crankshaft pulley centre bolt

another 60° and make sure that the

paint marks on the crankshaft pulley and crankshaft pulley

centre bolt are aligned.

11.Loosen the crankshaft

pulley centre bolt fully.

12.Tighten the

crankshaft pulley centre bolt to 110 N·m.

|

|

13.Make a paint mark on the

crankshaft pulley centre bolt.

14.Make a paint

mark on the bolt end at a position 60° from the paint

mark made

on the crankshaft pulley in the direction of tightening the

crankshaft pulley centre bolt.

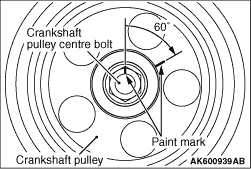

| caution |

- When the tightening angle

is smaller than the specified tightening

angle, the appropriate tightening

capacity cannot be

secured.

- When the tightening angle is larger than

the specified tightening angle, remove

the bolt to start from the beginning

again according to the

procedure.

|

15.Turn the crankshaft pulley centre bolt

another 60° and make sure that the

paint marks on the crankshaft pulley and crankshaft pulley

centre bolt are aligned.

|