|

|

1.Apply a small amount of

engine oil to the O-ring.

|

|

|

2.Install the O-ring to the

sensor with care to avoid damage to the O-ring.

|

|

|

3.Sufficiently remove the

sealant attached to the crank angle sensor.

|

|

4.Apply the sealant to the

crank angle sensor as shown in the

figure.

Specified sealant: ThreeBond 1207D or

equivalent

| note |

Install the crank angle sensor

immediately after applying sealant.

|

5.

| caution |

After the installation, until

a sufficient period of time (one hour or more)

elapses, do not apply the engine oil or water to

the sealant application area or start the

engine.

|

Tighten the sensor to the specified

torque.

Tightening torque: 9.5 ± 2.5

N·m

|

|

Put the water by-pass fitting

gasket tab in the position shown in the illustration to

install the water bypass fitting gasket.

|

|

| caution |

- Do not allow the sealant to run into the

thread end.

- Do not tighten the oil pressure switch

to the more torque than the specified

torque.

|

1.Sufficiently remove the sealant attached to

the oil pressure switch and the cylinder block threaded

hole.

2.Apply the sealant of 5 mm to the threaded

portion of the oil pressure switch as shown in the

illustration.

Sealant

Three bond

1141J or equivalent

3.Tighten the

oil pressure switch to the specified torque of 13 ± 5

N·m together with the oil cooler bracket.

|

|

Put the water outlet fitting gasket

tab in the position shown in the illustration to install the

water outlet fitting gasket.

|

|

1.

| caution |

Never use grease such as

engine oil to the o-ring.

|

Apply water to replace the o-ring and easily install

the new one.

2.Straightly insert the radiator

lower pipe into the water inlet fitting.

|

|

1.Put the water inlet pipe

gasket tab in the position shown in the illustration to

install the water pump assembly, the water pump gasket, the

water inlet pipe and the gasket.

|

|

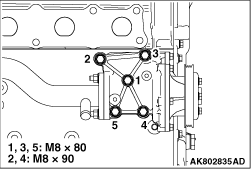

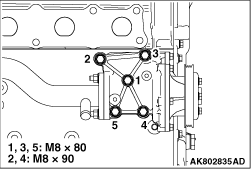

2.Install the water pump

gasket and the water pump assembly to the cylinder. Tighten

them to the specified torque of 24 ± 3 N·m in

the order shown in the illustration.

| note |

Pay attention to the

installation bolts because they are different in

length.

|

|

|

Install the thermostat with the

jiggle valve facing almost straight upwards.

|

|

1.Apply an appropriate and

minimum amount of sealant to the coolant temperature sensor,

not allowing the sealant to go beyond the specified

range.

Specified sealant:

LOCTITE

262, Three bond 1324N or

equivalent

2.Tighten the coolant

temperature sensor to the cylinder block to the specified

torque of 30 ± 9 N·m.

|