|

1.Make mating marks on the

radiator hose and the hose clamp. Disconnect the radiator

hose.

2.Disconnect the radiator hose.

|

|

Using special tool oil pressure

switch socket wrench (MB992118), removal the engine oil

pressure switch.

|

|

When loosening the nuts at both

ends of fuel injection pipe, hold the delivery holder

(for fuel injection pump side) and the fuel injection nozzle

(for fuel injection nozzle side)

with a wrench and loosen the nuts.

|

|

1.

| caution |

Never turn the crankshaft

anti-clockwise.

|

Turn the crankshaft clockwise, align the mating

marks on the camshaft sprocket with the

brilliant white mark ring plates on the timing chain to set

No. 1 cylinder to TDC (Top Dead Centre)

of its compression stroke.

|

|

2.

| caution |

- Do not lock the camshaft using the

timing chain.

- The camshaft sprocket bolt is left

threaded, so the arrow indicating its

tightening direction

is marked on the bolt head. To loosen

this bolt, turn the bolt to the opposite

direction of

the arrow.

- The timing chain must be attached to the

camshaft sprocket.

|

Hold the hexagonal part of the camshaft with an open

end wrench, loosen the camshaft sprocket

bolt, and then remove the camshaft sprocket with the timing

chain still attached.

3.Tie up the timing chain

and the camshaft sprocket with a cord to prevent the mating

mark misalignment.

|

|

1.Loosen the cylinder head

bolts in the shown sequence progressively, and then remove

the

cylinder head bolts.

2.Lift the cylinder head

assembly and cylinder head gasket straight without removing

the timing chain from the camshaft sprocket.

|

|

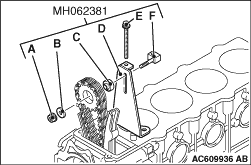

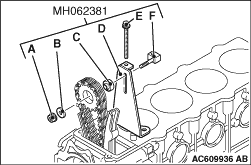

3.After the cylinder head

assembly and cylinder head gasket has been removed, use

special

tool camshaft sprocket holder kit (MH062381) to hold the

camshaft sprocket to prevent the timing

chain from sliding off.

- A: Nut

- B: Washer

- C: Spacer

- D: Adjust plate

- E: Bolt

- F: Nut

|

|

1.

| caution |

The thickness of the original

cylinder head gasket is selected according

to the protrusion amount of the piston.

Therefore, if the cylinder block, piston,

connecting

rod or crankshaft is replaced, the protrusion

amount may be changed. Always select a correct

gasket by measuring the protrusion amount.

(Refer to GROUP 11F -

Rocker Cover and Cylinder

Head Assembly  ). ).

|

To replace the cylinder head gasket only, select a

gasket of correct specification according

to the table below.

|

|

Notch specification

(fitted thickness

mm)

|

Part

number

|

A (1.35 ±

0.03 mm)

|

ME200751

|

B (1.40 ±

0.03 mm)

|

ME200752

|

C (1.45 ±

0.03 mm)

|

ME200753

|

D (1.50 ±

0.03 mm)

|

ME200754

|

|

2.

| caution |

Do not allow foreign material

to enter the engine coolant or oil passages

and the cylinder.

|

Clean the cylinder head assembly, the timing gear

case assembly, and the crankcase assembly

mating surfaces with a scraper or a wire brush.

|

|

3.

| caution |

After the engine oil pan is

installed, wait for at least one hour, and

then start the engine.

|

Apply the specified sealant to the upper side of the

mating surface between the timing

gear case and the crankcase assembly.

Specified

sealant: MITSUBISHI GENUINE PART MD970389 or

equivalent

4.

| caution |

When installing the cylinder

head gasket, be careful not to disturb the

sealant.

|

Immediately after applying the sealant, use the

cylinder head gasket to install the cylinder

head assembly to the crankcase.

|

|

5.

| caution |

The cylinder head bolts can be

reused up to 3 times. Therefore, the cylinder

head bolts with 3 punch marks already applied

must be replaced with new cylinder head bolts.

|

Apply punch marks to the bolt heads of the cylinder

head bolts.

|

|

6.Install the cylinder head

bolt washer to the cylinder head bolt so that the washer

chamfered

side faces as shown.

7.Apply a small amount of

engine oil to the cylinder head bolt thread and the

washer.

|

|

8.Tighten the cylinder head

bolts according to the following procedure (angle-tightening

procedure).

(1)

Tighten the bolts to 98 N·m in the order

shown.

Bolt size: Nominal diameter ×

length mm

- <Except 3, 6, 11, 14 >: 12 ×

105

- <

3, 6, 11, 14 >: 12 ×

125

(2)

Loosen the bolts fully in the reverse sequence to that

shown.

(3)

Tighten the bolts to 49 N·m in the order shown.

(4)

|

|

| caution |

- The bolt is not tightening

sufficiently if the

tightening angle is less

than a 90 degree

angle.

- If the tightening angle

exceeds the standard

specification, remove the

bolt and

start over from step

2.

|

|

Apply a paint mark to the heads of the cylinder head

bolts and cylinder head, then tighten

90 degree angle as shown.

(5)

Tighten in a 90 degree angle as shown in the instructions of

the figure, then check

to see that the paint mark on the head of the cylinder head

bolts and the paint mark on the

cylinder head is on a linear line.

(6)

|

|

| caution |

Whenever the

cylinder head bolts, are loosened

after the cylinder head

is installed, always apply the

sealant again.

|

|

Apply a small amount of engine oil to the thread and

the flange of bolts A, and tighten

them to A to 23 N·m.

|

|

|

1.Install the camshaft

sprocket to the camshafts with the timing chain

attached.

|

|

2.Hold the hexagonal part of

the camshaft with an open end wrench in the same manner as

removal.

3.Apply a small amount of engine oil to

the camshaft sprocket bolt thread and the flange,

and then tighten to the specified

torque.

Tightening torque: 88

N·m

|

|

Place the timing chain tensioner

gasket with its silicone print facing toward the timing

chain tensioner side.

|

|

1.Raise the cam, and then

push in the plunger, and lock the plunger using a

hook.

2.

| caution |

To install the timing chain

tensioner, always push in the plunger. If

you fail to do this, the timing chain will be

excessively tensioned, causing damage.

|

Install the timing chain tensioner to the cylinder

head.

3.

| caution |

If the crankshaft is turned

anti-clockwise after the timing chain tensioner

is installed, the plunger will be excessively

tensioned, causing the plunger to go beyond the

cam inside the timing chain tensioner.

|

Turn the crankshaft clockwise.

| note |

If the crankshaft is turned

clockwise after the timing chain tensioner is

installed, the plunger

is automatically unhooked. Then its internal

ratchet mechanism adjusts the timing chain

tension.

|

|

|

When tightening the nuts at both

ends of fuel injection pipe, hold the delivery holder

(for fuel injection pump side) and the fuel injection nozzle

(for fuel injection nozzle side)

with a wrench in the same manner as removal, and tighten the

nuts to the specified torque.

Tightening

torque: 23 N·m

|

|

1.

| caution |

Be careful not to block the

oil passage with sealant.

|

When reusing the sensor, apply the specified sealant

to the threads.

Specified sealant: 3M ATD Part

No. 8660 or equivalent

|

|

2.Tighten the engine oil

pressure switch together with the oil filter bracket to the

specified

torque, using special tool Oil pressure switch socket wrench

(MB992118).

Tightening torque: 19 ±

3 N·m

|

|

|

Insert the O-ring to pipe, and coat

the outer circumference of the O-ring with water.

|

|

1.Insert the radiator hose

as far as the projection of the thermostat case or water

outlet

pipe.

2.Align the mating marks on the radiator

hose and hose clamp, and then connect the radiator

hose.

|

).

). ).

). ).

). ).

). ).

). ).

). ).

).

).

). ).

). ).

). ).

). ).

).

).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

).

).

).