|

|

1.With the hose installed,

remove the power steering oil pump assembly from the engine

assembly. (Refer to GROUP 37 - Power Steering Oil Pump

Assembly  ). ).

|

|

|

2.After removing the power

steering oil pump assembly, secure it with a cord in the

location where the removal and installation of the timing

chain cannot be hindered.

|

|

|

1.With the hose installed,

remove the A/C compressor assembly from the engine assembly

(Refer to GROUP 55 - Compressor Assembly  ). ).

|

|

|

2.After removing the A/C

compressor assembly, secure it with a cord in the location

where the removal and installation of the timing chain

cannot be hindered.

|

|

|

3.Remove the A/C compressor

bracket from engine assembly (Refer to GROUP 55 -

Compressor Assembly  ). ).

|

|

|

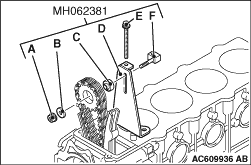

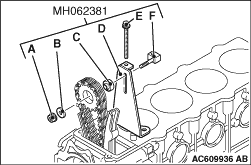

Remove special tool camshaft

sprocket holder kit (MH062381) that is installed when

removing

the cylinder head assembly and cylinder head gasket. Then,

remove the timing chain.

|

|

1.Using camshaft sprocket

holder kit (MH062381), support the camshaft

sprocket.

- A: Nut

- B: Washer

- C: Spacer

- D: Adjust plate

- E: Bolt

- F: Nut

|

|

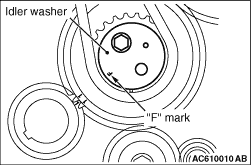

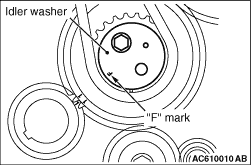

2.Check that the mating mark

“1” on the idler gear and sprocket assembly

is in alignment with that on the crankshaft gear.

|

|

3.

| caution |

Note that the timing chain has

one mark plate for the idler gear and sprocket

assembly side, and two mark plates for camshaft

sprocket.

|

Align the mating mark on the idler gear and sprocket

assembly with the brilliant white

mark ring plate on the timing chain.

|

|

4.Align the mark ring plates

with the camshaft sprocket mating marks.

5.Tie up

the timing chain and the camshaft sprocket with a cord to

prevent the mating

mark misalignment.

|

|

6.Install the idler washer.

The idler washer front mark "F" must face toward the front

of

the engine.

|

|

|

1.Clean the timing gear case

and the plate mating surfaces with a scraper or a wire

brush.

|

|

2.

| caution |

- After applying the sealant, install the

timing gear case

within 15 minutes.

- When installing the timing gear case, be

careful not to disturb the

sealant.

- Whenever the timing gear case mounting

bolts are loosened or tightened again

after

the timing gear case installation,

always apply the sealant again.

- After the timing gear case is installed,

wait for at least one hour, and then

start

the engine.

|

Apply a continuous bead of the specified sealant to

the timing gear case mating surface

as shown.

Specified sealant: MITSUBISHI GENUINE

PART MD970389 or equivalent

|

|

3.Install the mounting nuts

and bolts to the timing gear case at the shown

positions.

|

|

Name

|

Symbol

|

Size (Nominal

diameter × length

mm)

|

Flange bole

|

A

|

6 × 16

|

B

|

8 × 50

|

C*

|

8 × 60

|

D

|

8 × 75

|

E

|

8 × 80

|

F

|

8 × 85

|

G

|

8 × 90

|

H

|

10 × 35

|

Cap nut

|

I

|

-

|

|

| note |

*: Vehicle without

A/C.

|

|

).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

). ).

).

).

).