Pre-removal

Operation

- Power Steering Fluid Draining (Refer to

). ).

- Under Cover Removal (Refer to GROUP 51, Under Cover

). ).

- Front Differential and Propeller Shaft disconnection

(Refer to GROUP 25, Propeller

Shaft

). ).

- Wheel Speed Sensor Harness Bracket, Free Wheel

Actuator Connector and Hose disconnection

(Refer to GROUP 26, Differential Carrier and Free

Wheeling Clutch

). ).

- Differential Mount Bracket Front Mounting Bolts

removal (Refer to GROUP 26, Front

Differential Mount

). ).

|

Post-installation Operation

- Differential Mount Bracket Front Mounting Bolts

installation (Refer to GROUP 26,

Front Differential Mount

). ).

- Wheel Speed Sensor Harness Bracket, Free Wheel

Actuator Connector and Hose connection

(Refer to GROUP 26, Differential Carrier and Free

Wheeling Clutch

). ).

- Front Differential and Propeller Shaft Connection

(Refer to GROUP 25, Propeller

Shaft

). ).

- Under Cover Installation (Refer to GROUP 51, Under

Cover

). ).

- Fill Power Steering Fluid and bleed air (Refer to

). ).

- Check the Dust Cover for Cracks or Damage by Pushing

it with Finger.

- Check the Steering Angle (Refer to

). ).

|

|

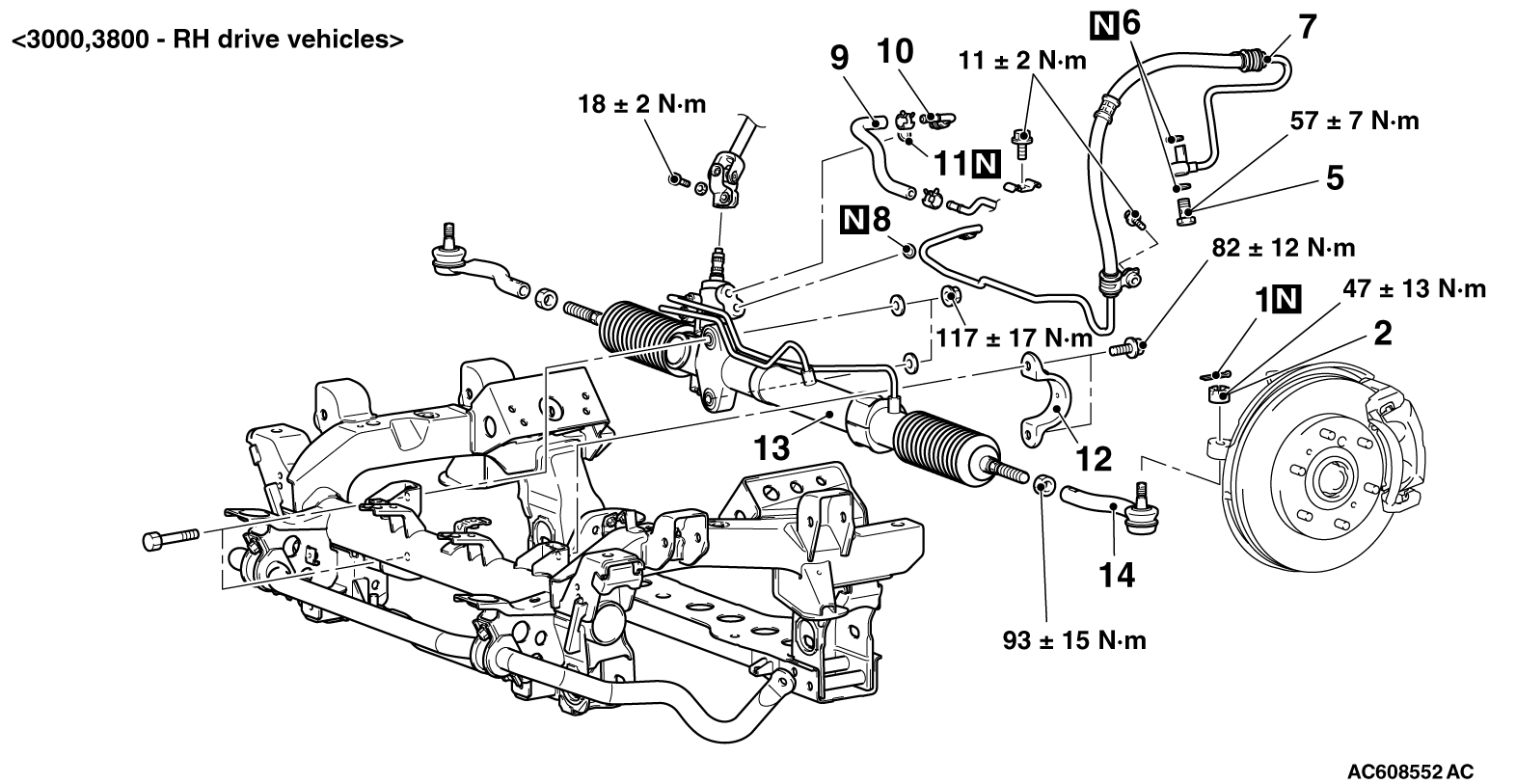

1.Install the special tool

ball joint remover (MB991897 or MB992011) as shown in the

figure.

|

|

2.Turn the bolt and knob as

necessary to make the jaws of the special tool parallel,

tighten

the bolt by hand and confirm that the jaws are still

parallel.

| note |

When adjusting the jaws in

parallel, make sure the knob is in the position

shown in the

figure.

|

3.Tighten the bolt with a wrench to

disconnect the tie rod end.

|

|

1.Align the mating marks on

the gear box, return tube assembly and pressure tube

assembly

when installing.

2.Install so that the mating

marks and upward.

|

|

3.Install so that the

markings are faced upward.

|

|

Screw the tie rod to the dimension

shown in the illustration and secure it temporarily

with the jam nut.

| note |

Tighten the locknut to the

specified torque after installing the gearbox

onto the body

and adjusting the toe-in.

|

Reference value A:

<Short wheel

base> 46mm

<Long

wheel base> 41mm

|

) and Air

Bag Module(s) and Clock Spring (

) and Air

Bag Module(s) and Clock Spring ( ). Centre

the front wheels. Failure

to do so may damage the SRS clock spring and render the SRS

system inoperative, risking serious

injury.

). Centre

the front wheels. Failure

to do so may damage the SRS clock spring and render the SRS

system inoperative, risking serious

injury.