|

Use special tool oil filter wrench

(MH061590) or commercially-available tool to remove

the oil filter.

|

|

Use special tool oil pressure

switch wrench (MD998012) to remove the engine oil pressure

switch.

|

|

Use special tool oil pressure

switch wrench (MB992118) to remove the engine oil pressure

switch.

|

|

|

1.Remove the oil pan

mounting bolts.

|

|

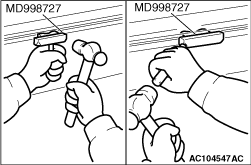

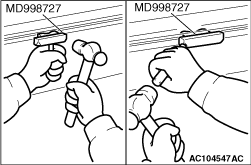

2.

| caution |

Do not use special tool oil

pan FIPG cutter (MD998727) in area A of the

oil pan. Using the special tool in area A may

cause deformation of the front case because the

front case is made of aluminium.

|

Tap the special tool into the range (B) between the

cylinder block and the oil pan, and

then slide the special tool sideways.

| note |

If any surrounding parts

interfere with the removal, there is no need to

use the special

tool.

|

3.Remove the oil pan.

|

|

1.Remove the plug on the

right side of cylinder block.

2.Insert a phillips

screwdriver into the plug hole to lock the silent shaft in

position.

3.Remove the flange bolt.

|

|

Put alignment marks on the inner

and outer rotors for reference in reassembly.

|

|

|

1.Apply engine oil to the

balancer shaft drive and driven gears.

|

|

2.Install the balancer shaft

drive and driven gears to the front lower case. Make sure

that

the alignment marks are in line.

|

|

Install the outer rotor in the same

direction as before noting the mark put at the time

of removal. Apply engine oil to the entire rotor

surface.

|

|

|

1.Apply engine oil to the

oil seal outer surface.

|

|

2.Using special tool

balancer shaft drive gear oil seal guide (MD998385), drive

in with

a socket wrench.

|

|

1.Attach special tool

crankshaft front oil seal guide (MD998383) to the crankshaft

and apply

engine oil to the outer surface of the

tool.

2.Using special tool crankshaft front oil

seal installer (MD998382), install the front

oil seal into the front lower case.

|

|

1.Insert a phillips

screwdriver into the plug hole to block the balancer

shaft.

2.Install the flange bolt and tighten to

the specification.

3.Remove the screwdriver and

install the plug.

|

|

Apply engine oil to the oil seal

outer surface and drive in with a socket wrench.

|

|

|

Use either an oil pan gasket or a

sealant for installing the oil pan. Install the oil

pan in accordance with the following procedure

respectively.

|

|

1.<Sealant>

(1)

Remove sealant from the oil pan and cylinder block

surfaces.

(2)

Apply a Φ4 ± 1 mm wide bead of sealant to the

entire circumference of

the oil pan flange.

Specified sealant:

ThreeBond 1217G or equivalent

|

|

| note |

Install the oil

pan immediately applying

sealant.

|

|

(3)

|

|

| caution |

After the

installation, until a sufficient

period of

time (one hour or more) elapses, do

not apply the oil or water to the

sealant application area

or start the engine.

|

|

Install the oil pan.

(4)

Tighten the oil pan bolts to the specified

torque.

Tightening torque: 9.0 ± 3.0

N·m

2.<Gasket>

(1)

Remove sealant from the oil pan and cylinder block

surfaces.

(2)

Install the oil pan gasket so that its fluorine-coated

surface faces the cylinder

block side.

(3)

Install the oil pan.

(4)

Tighten the oil pan bolts to the specified

torque.

Tightening torque: 9.0 ± 3.0

N·m

|

|

Position the tab as shown in the

illustration.

|

|

1.

| caution |

Use care not to allow the

sealant to plug the oil passage.

|

Apply sealant to the engine oil pressure switch

thread.

Specified sealant: ThreeBond 1141J or

equivalent

| note |

Install the engine oil

pressure switch immediately after applying

sealant.

|

2.

| caution |

After the installation, until

a sufficient period of

time (one hour or more) elapses, do not apply

the oil or water to the sealant application area

or start the engine.

|

In the same manner as removal, use special tool oil

pressure switch wrench (MB992118)

to tighten the engine oil pressure switch to the specified

torque.

Tightening torque: 10 ± 2

N·m

|

|

1.

| caution |

Do not get any oil (rust

prevention oil etc.) on the area as shown in the

figure to prevent

the influence of switch function.

|

| caution |

Use care not to allow the

sealant to plug the oil passage.

|

Apply sealant to the engine oil pressure switch

thread.

Specified sealant: ThreeBond 1141J or

equivalent

| note |

Install the engine oil

pressure switch immediately after applying

sealant.

|

2.

| caution |

After the installation, until

a sufficient period of

time (one hour or more) elapses, do not apply

the oil or water to the sealant application area

or start the engine.

|

In the same manner as removal, use special tool oil

pressure switch wrench (MD998012)

to tighten the engine oil pressure switch to the specified

torque.

Tightening torque: 10 ± 2

N·m

|

|

1.Install the engine oil

pressure switch terminal in the direction shown in the

illustration.

2.Tighten the engine oil pressure

switch terminal mounting screw to the specified

torque.

Tightening torque: 3.5 ± 0.4

N·m

|

|

|

1.Clean the oil filter

installing surface on the cylinder block side.

|

|

2.Apply a small amount of

engine oil to the new oil filter gasket.

3.For the

specified tightening torque, refer to the caution label

attached on the oil

filter.

4.Tighten the oil filter until the gasket

contacts with the installation surface.

5.In the

same manner as removal, use special tool oil filter wrench

(MH061590) or commercially-available

tool to tighten the oil filter to the specified

torque.

|