|

Using general service tool, remove

the oil filter from the oil filter bracket.

|

|

1.Remove the oil pan

bolts.

2.Insert the special tool Oil pen remover

(MD998727) into the joint between the cylinder

block and oil pan by tapping the tool with a

hammer.

3.Remove the oil pan by tapping an edge of

the special tool Oil pen remover (MD998727)

with a hammer to move it sideways.

|

|

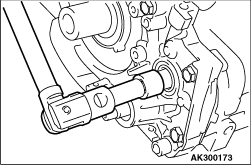

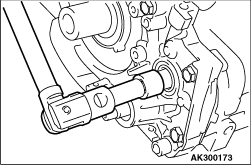

Fit the teeth of the special tool

in notches of the plug as shown in the

drawing and support the tool with the special tool to loosen

the plug.

- Plug wrench (MD998162)

- Plug wrench retainer (MD998783)

|

|

1.Remove the plug on the

side of the cylinder block.

2.Insert a Phillips

screwdriver (shank diameter 8 mm) into the plug hole to lock

the

counterbalance shaft.

|

|

3.Loosen the flange

bolt.

|

|

| caution |

Be sure to remove the front

bearing first. If it has not

been removed, special tool Silent shaft bearing

puller (MD998372) cannot be used for rear

balance

shaft bearing removal.

|

Using special tool Silent shaft bearing puller

(MD998371), remove the counterbalance shaft

front bearing from the cylinder block.

|

|

1.Using special tool Silent

shaft bearing puller (MD998372), remove the right

counterbalance

shaft rear bearing from the cylinder block.

Using special

tools, remove the left counterbalance shaft rear bearing

from the cylinder

block.

- Silent shaft bearing puller (MD998372)

- Bearing installer stopper (MB991603)

|

|

1.Install special tool

Silent shaft bearing installer stopper (MB991603) to the

cylinder

block.

2.Apply engine oil to the rear bearing

outer surface and bearing hole in the cylinder

block.

3.Using special tool Silent shaft bearing

installer (MD998705), install the rear bearing.

| note |

The left rear bearing has no

oil holes.

|

|

|

1.Install special tool the

guide pin of the Silent shaft bearing installer (MD998705)

in

the threaded hole of the cylinder block as shown.

|

|

2.Align the ratchet ball of

the special tool with the oil hole in the rear bearing to

install

the bearing of the special tool.

3.Apply engine

oil to the bearing outer surface and bearing hole in the

cylinder block.

|

|

4.Using special tool,

install the rear bearing. Make sure that the oil hole of the

bearing

is aligned with the oil hole of the cylinder block.

|

|

1.Remove the rear bearing

installing portion from the special tool Silent shaft

bearing

installer (MD998705).

|

|

2.Install special tool the

guide pin of the Silent shaft bearing installer (MD998705)

in

the threaded hole of the cylinder block as shown.

|

|

3.Align the ratchet ball of

the special tool with the oil hole in the rear bearing to

install

the bearing of the special tool.

4.Apply engine

oil to the front bearing outer surface and bearing hole in

the cylinder.

|

|

5.Using special tool,

install the rear bearing. Make sure that the oil hole of the

bearing

is aligned with the oil hole of the cylinder block.

|

|

Using a suitable socket wrench,

install the counterbalance shaft oil seal into the front

case.

|

|

Using a suitable socket wrench,

install the oil pump oil seal into the front case.

|

|

Using special tool Crankshaft front

oil seal installer (MD998375), install the crankshaft

front oil seal into the front case.

|

|

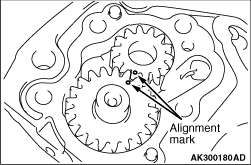

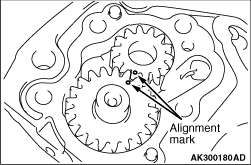

Install the oil pump gears into the

front case and align the alignment marks.

|

|

1.Set special tool

Crankshaft front oil seal guide (MD998258) on the front end

of crankshaft

and apply a thin coat of engine oil to the outer surface of

special tool.

2.Apply engine oil to the lip of the

crankshaft front oil seal.

|

|

3.Install the front case

carefully not to damage the oil seal.

|

|

4.

| caution |

Carefully install the

tightening bolts because of the different

length respectively.

|

Tighten all flange bolts to the specified

torque.

Tightening torque: 23 ± 3

N·m

|

|

1.Insert a Phillips head

screwdriver (shank diameter 8 mm) into the hole in the left

side

of the cylinder block to lock the counterbalance

shaft.

|

|

2.Secure the oil pump driven

gear onto the left counterbalance shaft by tightening the

flange

bolt to the specified torque.

Tightening

torque: 36 ± 3 N·m

3.Pull out

the screwdriver and screw in the plug.

|

|

1.Install a new O-ring to

the groove of the front case.

2.Install the plug

to the front case.

3.Use the special tool to

tighten the plug to the specified torque.

- Plug wrench (MD998162)

- Plug wrench retainer (MD998783)

Tightening torque: 23 ± 3

N·m

|

|

|

1.

| caution |

Do not apply FIPG over

remaining old FIPG. Doing so could

result in oil leakage.

|

Thoroughly remove old FIPG from the gasket surfaces

of the cylinder block and oil pan.

|

|

2.

| caution |

Too much FIPG will squeeze

out, blocking coolant or oil passages,

while too thin a bead could result in

leakage.

|

Apply a 4 mm diameter bead of FIPG to the flange

surface all around the oil pan.

Specified

sealant:

Mitsubishi Genuine Part

No.MD970389 or equivalent

| note |

In the grooved areas on the

oil pan flange, apply FIPG bead along the center

of the groove.

|

|

|

3.Install the shorter bolts

in the locations indicated in the drawing.

|

|

|

1.Clean the installation

surface of the filter bracket.

|

|

2.Apply engine oil to the

o-ring of the oil filter.

|

|

3.Using general service

tool, Install the oil filter to the bracket and tighten it

to the

specified torque.

Tightening

torque

Part number MD356000 filter: 14

± 2 N·m

Other Mitsubishi Genuine

filter: 17 ± 3

N·m

4.If a torque wrench

cannot be used use the following procedure:

(1)

Screw in the oil filter until its o-ring contacts the oil

filter bracket.

(2)

Tighten the oil filter as follows:

Mitsubishi

Genuine filter: 3/4 turn

|

|

| caution |

If the gasket is installed in

the wrong direction, oil leaks will

occur.

|

Install the drain plug gasket in the direction

shown.

|